Chip Conveyor

Chip conveyor business

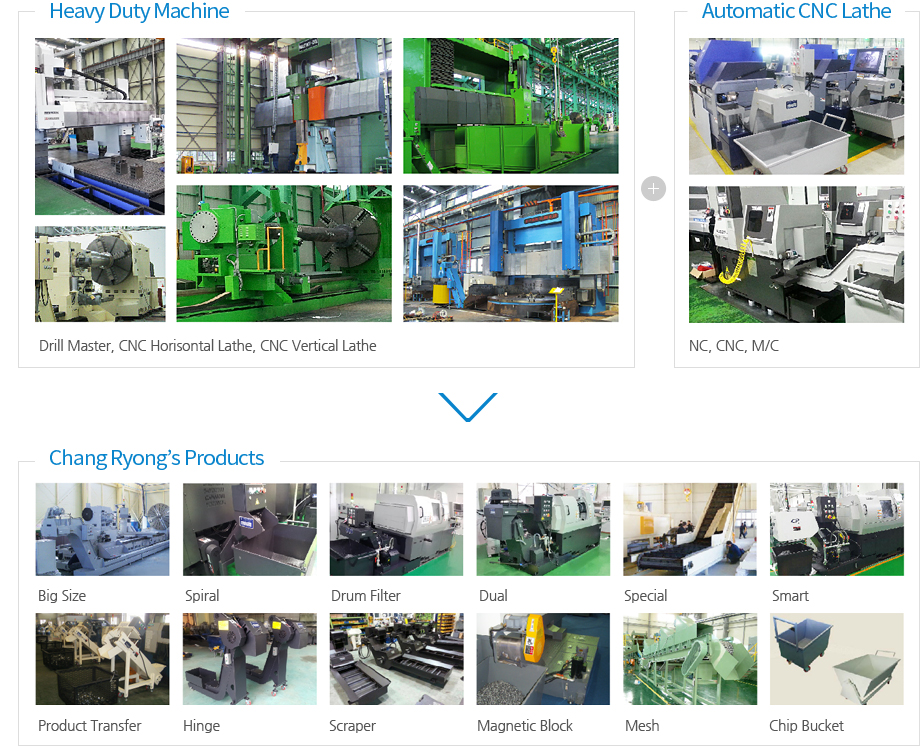

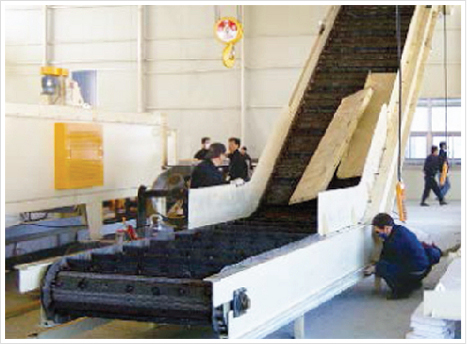

The chip conveyor business is the core business of Chang Ryong Machinery for developing, designing, manufacturing and installing peripheral facilities. We mainly focus on manufacturing chip conveyor, coolant percolation mechanism, chip processing devices supplied to small machine tools such as CNC automatic lathe based on the domestic vehicle industry development as well as large machine tools such as large drill master, CNC horizontal lathe and vertical lathe that represents the machine tool industry.

Quality renovation is achieved with the first goal of customer surprise through endless technical development and user-centered design.

Chip conveyor business designs and manufactures a variety of chip conveyors according to the functions, purposes, chip‘s sizes and types of manufacturing equipment.

We manufactures from large conveyors over 100 meters of line conveyors to small inflight product transfer conveyors in the CNC automatic lathe.

In compliance with the current industrial flow to raise the precision of processed products, the chip‘s receptive ability from the past simply chip discharging function-centered conveyors to separation of chip and cutting oil, filtering, compression and various types of chips develop along with the important functions of conveyors. Chang Ryong Machinery is not satisfied with manufacturing products through the standardized mass production system but reflects user‘s opinions and keeps consistent research in post-Fordism and focuses on the production of the best quality conveyors.

- Appropriate for dealing with relatively large scale long / short chips that are discharged from processing large machine tools such as drill master, CNC horizontal lathe and CNC vertical lathe.

- It is possible to manufacture a produce with a length of 20~100 meters and it is applied to centralized line conveyors.

- Installed to a lower part of bit to make better use of space

- Economical efficiency is excellent from customized manufacturing according to machines.

- Supply high quality and high efficient products from field customized production in compliance with factory environment.

- Coolant tanks are manufactured by option.

- Appropriate for long / short chips discharged from CNC lathe and M/C processing.

- Work efficiency is raised by reducing the volume of chips.

- Discharge of cutting oil is reduced to bring about reduction of processing costs and effect of factory environment improvement.

- Installable in small space and have maximized effect of chip discharge.

- Customized production according to machines results in excellent economical efficiency.

- A torque miter is attached to prevent overloads and the conveyor is protected.

- Supply high quality products at lowest prices thanks to standardization and mass production.

- Coolant tanks are manufactured by option.

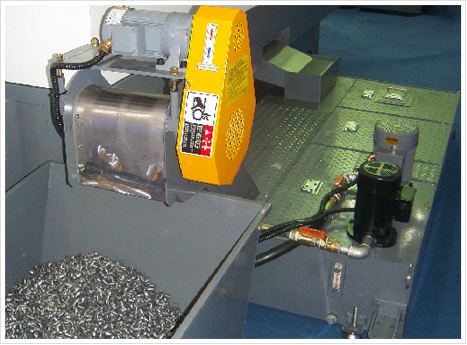

- Compared to general coolant filtering systems, a separate filtering device is not necessary.

- The degree of chip filtering of a coolant in a small area can be improved and consecutive filtering is possible.

- Due to installation of a flushing device to prevent the blockage of a filter, stable coolant supply is always possible.

- Chip treatment of various materials such as aluminum chip, steel chip, non-ferrous metal processing chip and combined processing chip becomes possible.

- According to the filter degree to use, various filters of 50, 75, 100, 150, 200㎛ can be selected.

- Net filter of the PE system and etching filter of the SUS system are used.

- The precipitation chip is discharged outside by the scraper attached to the conveyor chain.

- Supply high quality products at lowest prices thanks to standardization and mass production.

- Coolant tanks are manufactured by option.

- Dream filter conveyor + hinge conveyor is very proper for dealing with long / short /clip / fine chip.

- Compared to general coolant filtering systems, a separate filtering device is not necessary.

- The degree of chip filtering of a coolant in a small area can be improved and consecutive filtering is possible.

- Due to installation of a flushing device to prevent the blockage of a filter, stable coolant supply is always possible.

- Chip treatment of various materials such as aluminum chip, steel chip, non-ferrous metal processing chip and combined processing chip becomes possibl.e

- According to the filter degree to use, various filters of 50, 75, 100, 150, 200㎛ can be selected.

- Net filter of the PE system and etching filter of the SUS system are used.

- The precipitation chip is discharged outside by the scraper attached to the conveyor chain.

- Supply high quality products at lowest prices thanks to standardization and mass production.

- Coolant tanks are manufactured by option.

- Dream filter conveyor + screw conveyor is very proper for dealing with long / short /clip / fine chip.

- Compared to general coolant filtering systems, a separate filtering device is not necessary.

- The degree of chip filtering of a coolant in a small area can be improved and consecutive filtering is possible.

- Due to installation of a flushing device to prevent the blockage of a filter, stable coolant supply is always possible.

- Chip treatment application of various materials such as aluminum chip, steel chip, non-ferrous metal processing chip and combined processing chip becomes possible.

- According to the filter degree to use, various filters of 50, 75, 100, 150, 200㎛ can be selected.

- Net filter of the PE system and etching filter of the SUS system are used.

- The precipitation chip is discharged outside by the scraper attached to the conveyor chain.

- Supply high quality products at lowest prices thanks to standardization and mass production.

- Coolant tanks are manufactured by option.

- Manufacture customized conveyors applicable to large machine tools.

- Possible to deal with irregular and specialized chips in size and shape of discharged chips.

- Possible to process stable products through structural design in compliance with factory environment.

- Installed to a lower part of bit to make better use of space and maximize the effect of chip discharge.

- Economical efficiency is excellent from customized manufacturing according to machines.

- Coolant tanks are manufactured by option.

- Mainly used for transfer of processed products and heavy weight products.

- Appropriate for cutting processed products or vestige transfer and used for disposing press scrap.

- Convenient to connect or transfer a variety of conveyors and installable to processing environment.

- Excellent economical efficiency due to customized production.

- A torque miter is attached to prevent overloads and the conveyor is protected.

- Mainly used for transfer of processed products, forging and heavy weight products.

- Appropriate for cooling transfer of heated forging.

- Excellent functionality even in undesired working environment.

- Excellent economical efficiency due to customized production.

- Appropriate for long / short chips discharged from CNC lathe and M/C processing.

- Also used for disposing small press scrap.

- No frequent breakdown from using high strength and oil resistant hinge chain and long life cycle.

- A torque miter is attached to prevent overloads and the conveyor is protected.

- Supply high quality products at lowest prices thanks to standardization and mass production.

- Coolant tanks are manufactured by option.

- Used for disposing short chips discharged from CNC lathe, exclusive machine and M/C processing.

- Appropriate for disposing casting processed chips.

- Precipitate chips on the conveyor floor and remove chips by a precision scraper.

- Widely used due to no frequent breakdown and excellent filtering ability.

- Possible to manufacture the magnet type to improve filtering.

- A torque miter is attached to prevent overloads and the conveyor is protected.

- Supply high quality products at lowest prices thanks to standardization and mass production.

- Coolant tanks are manufactured by option.

- Appropriate for disposing shear type chips discharged from hobbing and broaching M/C processing.

- Also used for transferring small press scrap.

- Efficient for disposing non-aqueous coolant chips with high viscosity.

- Maximize the effect of chip discharge using a magnet.

- Excellent economical efficiency due to customized production.

- Supply high quality products at the lowest price through part standardization.

- A torque miter is attached to prevent overloads and the conveyor is protected.

- Supply high quality products at lowest prices thanks to standardization and mass production.

- Coolant tanks are manufactured by option.

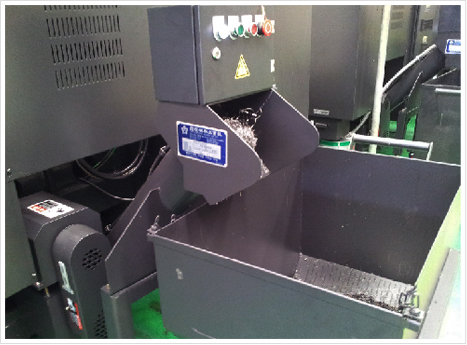

- Bucket to receive chips discharged from a conveyor and transfer them outside.

- Easy to move with cast wheels attached, and a large bucket can be transferred by a forklift.

- Various buckets such as standard, revolving, no conveyor and specially customize types.

- Separate chips and cutting oil from a mesh and a valve.