Chip Disposal System

Introduction to the business department of the chip disposal system

The chip disposal system business manufactures and delivers line equipment for factory automation based on chip conveyor manufacturing technology through the suggestion of the centralized chip disposal system and the coolant system for automation disposal of chips and cutting oil. As aprofessional company specializing in peripheral facilities of machine tools with 25 years tradition based on accumulated skills, know-how and competent individuals, we promise to suggest user-centered systems that are optimized by considering a process and characteristics.

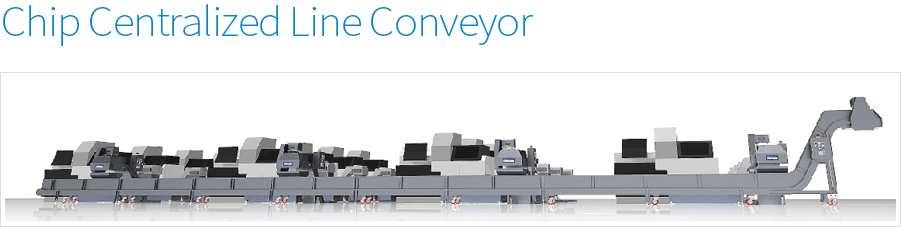

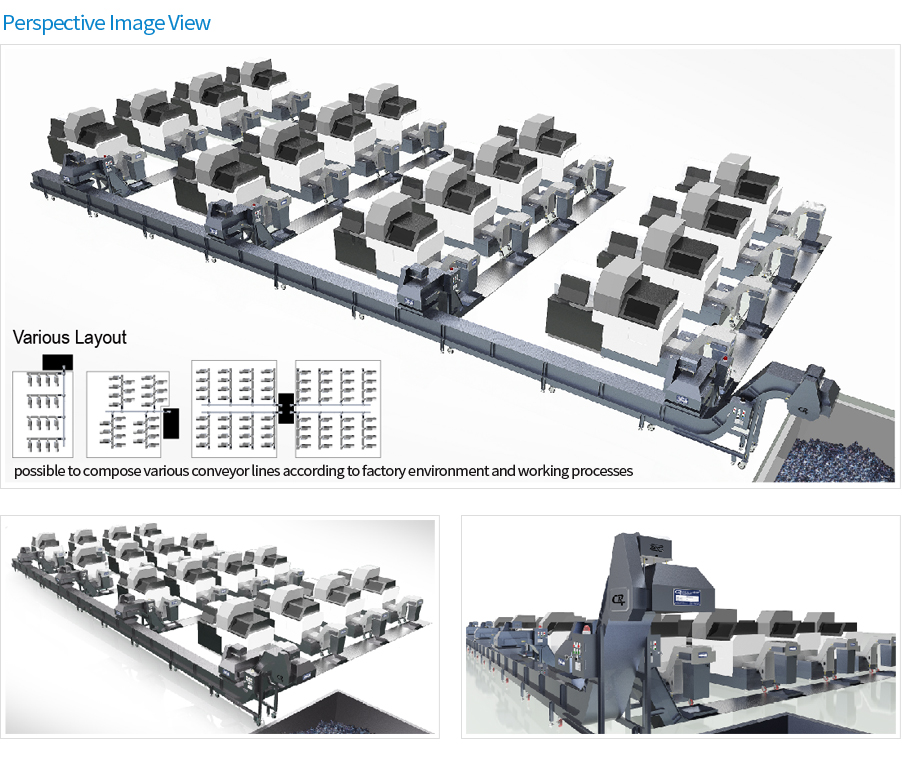

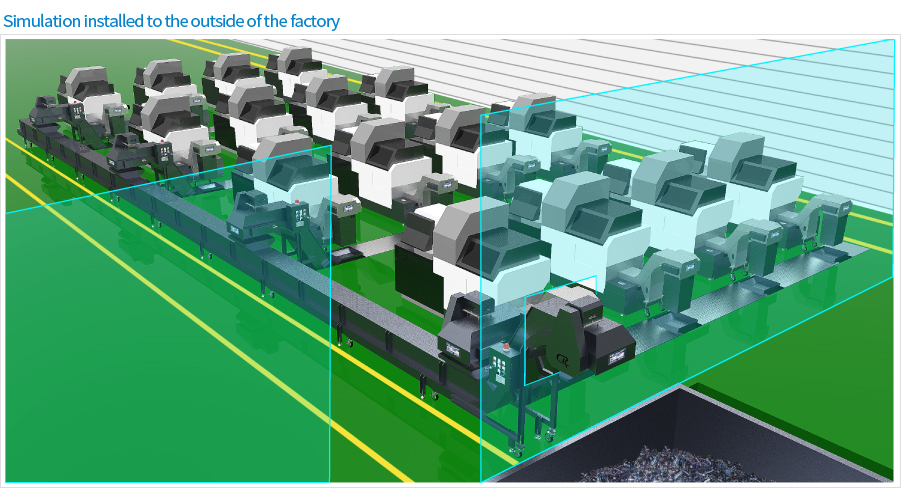

It is a chip disposal automation system to bring about the effects of cost reduction and productivity improvement through personnel reduction for operating a factory.

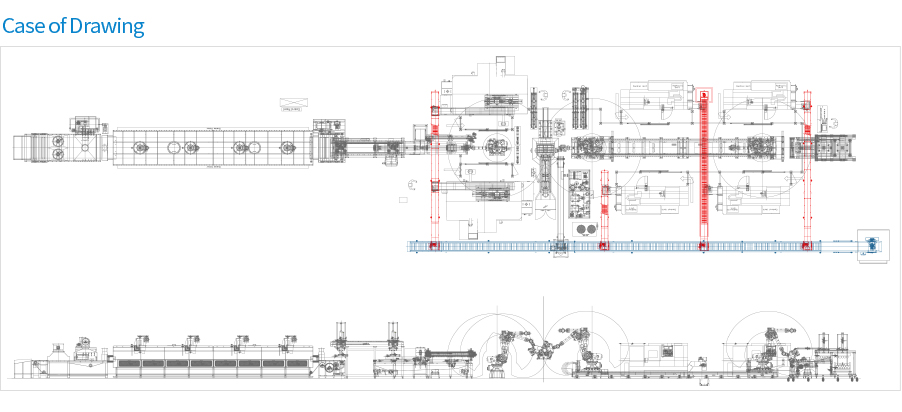

This system moves chips discharged from each machine tool to a central main conveyor through a small conveyor, and finally transfer chips to the outside of a factory without allocating manpower. Moreover, due to installation of a conveyor below the floor, a working place can be utilized efficiently, and the blockage of cutting oil can prevent the contamination of working environment and maintain comfortable environment.

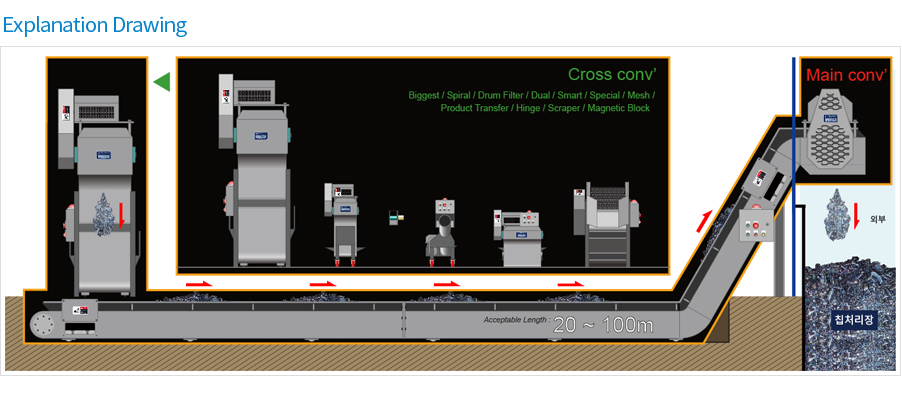

We promise to offer our customers the best satisfaction for improving working environment and productivity through customized line design in compliance with your factory environment and manufacturing process.

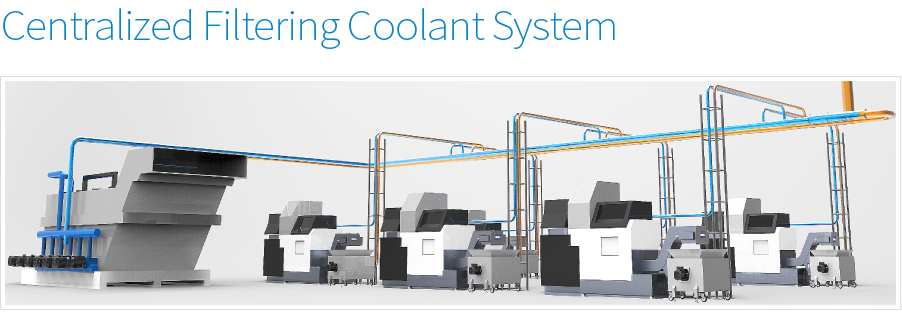

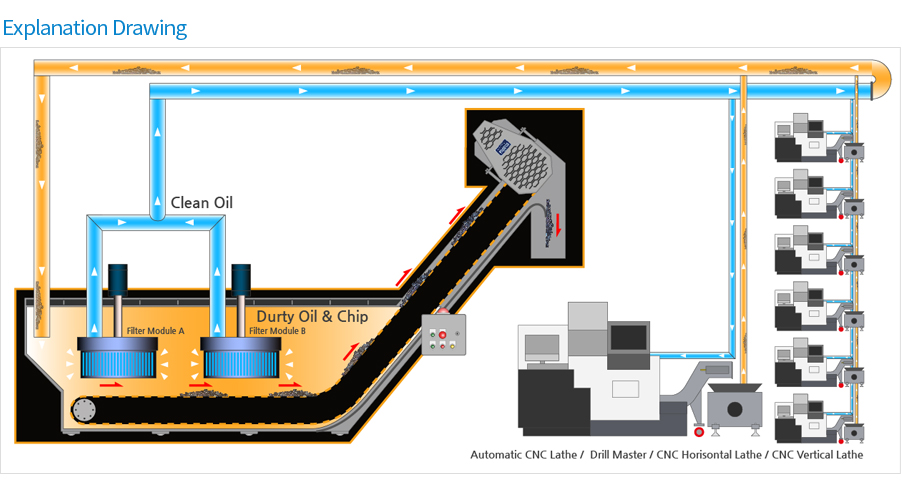

Paper filter, drum filter and magnet separator are used for small cutting oil disposal facilities, and the application of the centralized filtering system is efficient for large scale cutting oil disposal. The purpose of the use of large cutting oil disposal equipment is to supply the most optimized stable quality through the reduction of operational costs (equipment cost, operating expenses, maintenance costs and machined chip disposition man-hour) and environment improvement (prevention of machined chip expansion, extension of cutting oil life cycle, reduction of an area to install a facility). Discharge methods are divided into buried, pump and compound types and selective installation in compliance with your environment is possible.

therefore particularly well suited for the integration in a chip disposal system and easy to retrofit as expansion or upgrade of the filtering capacity.

The configuration of the vacuum filter offers a higher percentage purity without the use of filter auxiliary consumables.

This does not only drastically lower the operating costs but also makes the system less sensitive to any cracks or holes in the filter mat.